Anatomy

of a Quality Embroidery Design

When I first got started

with my embroidery machine I didn't know anything about designs.

All I knew is that some of them were very expensive and others were

free. Some seemed easy to sew and others gave me trouble:

the fabric bunched up or the satin stitch was skinny and didn't grip my

applique fabric well. Some of them were very pretty and

professional-looking while others looked sloppy and choppy. Some

of them left with me with a colorful web of jump stitches to trim or left me

wondering "why did this design just do that?" It was after I made

my own list of qualities that make up a good design that I decided to

start learning to create my own designs.

Eight years of

digitizing experience (and still learning every day!), lots and lots of

practice, classes from dealers, college-level classes, conversations

with other digitizers and thousands and thousands of designs all go into

this list of what to look for and what to avoid.

I love creating embroidery

designs and I especially love creating designs that are the best

quality. So good that you can tell the difference right away.

I wholeheartedly believe that the stitching experience is just as

important as the finished product! I am very thankful for the

amazing, positive feedback that I receive from customers who can tell

the difference. Along with the positive feedback often comes "Now

that I know what a good design is, I don't want to stitch anything less.

How can I recognize a high quality embroidery design? Are there

any signs of a poor design that I can look out for when shopping?"

I'm going to do my best to

show you some things to look for.

Most of these criteria are

agreed on by 99% of experienced digitizers. Some are personal

preferences that I think you will find helpful.

Please keep in mind that different

digitizers have different ways of doing things so there is not a set

"right way" and "wrong way", but experienced digitizers will agree that

some qualities are absolutely necessary when creating a good design,

regardless of technique or personal preference.

Let's get started with the

basics...

What is digitizing?

Digitizing is the art of creating design files that are read by

embroidery machines.

What is a digitizer?

A

digitizer is someone who creates design files. A digitizer can

create files from their own artwork or they can use commercial clipart

to base the designs on.

What is digitizing software?

Digitizing software is a computer program that the digitizer uses to

create design files. The digitizer must use the software to

communicate with the machine. We must tell it where to stitch, how

to stitch, in which direction, in which order and which color. We

tell it when and where to start and when and where to stop and how close

together to place the stitches. There

are too many factors to list. A digitizer has many, many elements

to consider when creating a design. Different digitizing software

packages allow different types of control over a design. Some are

very simple and aimed at home-based embroiderers and hobbyists while

others are very technical and are aimed at embroidery and digitizing

professionals. In this article I will use Brother's PE-Design as

an example of home-based software and Wilcom's Embroidery Studio 2 as an

example of professional software.

When I first started

embroidering, I thought that I could simply find an image on the

internet and send it to my machine and that somehow my machine would

instinctively know exactly what to do. It wasn't long before I

realized that this is FAR from true! A digitizer must take the

image and re-draw it using commands that an embroidery machine can

understand. We can't simply convert an image file to an embroidery

file. Well...there are programs that will do that but let me show

you why this very rarely yields good results. Taking an image file

and using software to automatically create and embroidery file is called

Auto-Digitizing.

Auto-digitizing does not

allow the digitizer to control the design. We can't tell it where

to start and stop or which direction to stitch or which type of stitch

to use. Adjustments can me made but it is usually more

time-consuming to fix an auto-digitized design than it would be to

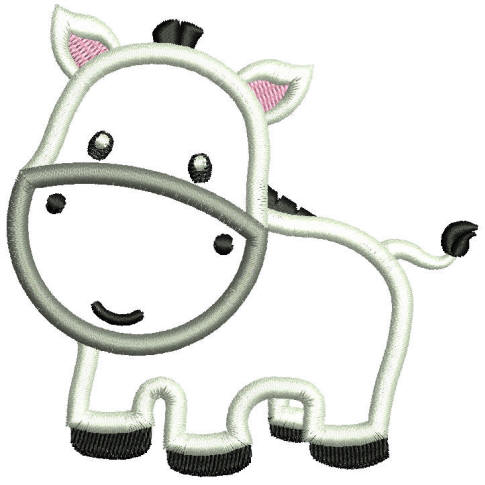

simply start from scratch. I'm going to use high-quality

commercial clipart of a zebra throughout this article to illustrate

different digitizing results.

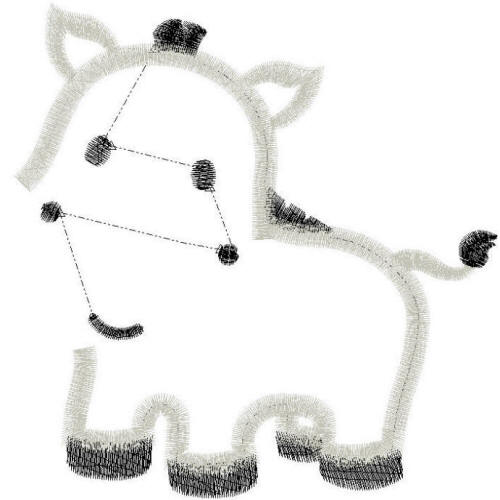

In this example I

ran the zebra image through Brother's PE-Design Software. I used

the "image to stitches" function.

The results are nothing

short of terrible. (You can download this disaster

HERE if

you would like to see for yourself)

So, what wrong with this

design? First of all, it isn't very nice-looking. There

isn't much definition. The stitches appear choppy and gapped.

There are some other flaws that you can't see here but that will

absolutely contribute to the poor quality of this design. Look at

the white background area that the software added. This should be

negative space (nothing there). The stitches are running at

different angles and are different lengths. THERE IS NO UNDERLAY

STITCHING ANYWHERE <--BIG Problem!

What is underlay stitching?

Underlay stitches are stitches that run before a block of stitching.

They are usually more widely-spaced than fill stitches. Think of

the underlay stitches as your foundation. They are there to

support the stitches and prevent the design from shifting, puckering,

and many other disastrous outcomes (think hole in a tee shirt!).

You don't want to build a house without a foundation.

Let's look at the black.

First, it is full of jump stitches.

What are jump stitches?

Jump stitches are the long stitches that run when the machine stitches

in

one area and then picks up and moves to start stitching in a different

area. Some machines will trim these stitches for you.

A skilled digitizer will

minimize jumps by telling the machine to make the smallest jumps between

objects. We must sequence the elements of a design so the they

stitch in order by how close they are to each other. Think about

crossing a river by stepping on stones. You are going to want to

step to the next closest stone, not take one giant leap forward over

five stones and then three backward and two forward, right? Almost

all of the long jumps in this design could be minimized. I'll

explain more about that later...

Still looking at the

black...look at the way the stitch angles change direction and how the

stitch types are different. Some are a fill stitch (the stitch

type you see in the white background area) while some are satin stitch,

the smoother stitching that you see on some of the stripes,

inconsistently. The stitch areas are broken up into chunks rather

than continuous, free-flowing shapes. A good example would be the

eyes.

The software added some

yellow in there as well as some brown on the side of the face and pink

under some of the stripes. There are 72 color changes in this

design! I don't think I need to explain what a pain THAT is!

There are many other issues with this design, too many to describe.

Overall

results? Terrible (in my opinion).

Next, I ran the same image

through Wilcom's Embroidery Studio 2 "Smart Design".

The results are not as

unattractive as the first auto-digitized design but this is still FAR

from a quality design.

(You can download this

less-than-quality design

HERE) The scary thing about a design like

this is that you might actually purchase a design that looks like this!

It's not so terrible that you would write it off as a "bad design" right

away.

So, what wrong with this

design? Again, THERE IS NO UNDERLAY STITCHING ANYWHERE <--BIG

Problem! You're going to get shifting

and gaps and thread breaks. You don't want to build a house without a foundation.

The angle of the white,

pink, and grey stitches is the same. All of the stitching is

running in the same direction! <--Another BIG Problem!

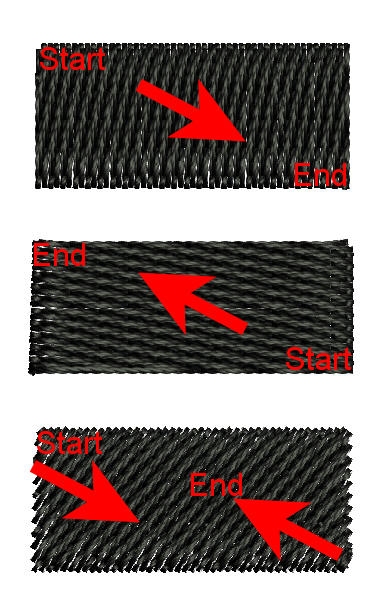

What are stitch angle and direction and why do they matter?

Stitch angle is the direction that the stitches are placed, horizontal,

vertical, and every angle in between. Different angles products

different effects. Stitch direction is the direction that the

stitches run as they sew. Start on the upper left, end on the

lower right, start on the lower right end on the upper left, or some

designs will start on one side and fill partial areas and then travel to

the other end and change direction to come back and meet in the middle.*

*My personal preference is

to avoid designs that do that because they tend to gap where the

stitches meet, especially if the filled stitch area is large.

Sometimes it is an intentional move by the digitizer to minimize a jump

stitch but many times it is a

software default that the digitizer didn't take the time to replace with

his/her own settings.

Stitch direction is also important because a design must

have balanced angles and directions to avoid shifting and bunching.

If all of a design's stitches run at a 45 degree angle from left to

right then there is going to be a lot of left to right, top to bottom

movement in the hoop. If the designs has outlines or details they

will most likely be off, and it can cause some distortion of the

design's shapes.

If you see a design that

has the same angle on all of the stitches then I would say it is safe to

assume that the stitch directions are also going to be automatic or all

the same and I, personally, would avoid that design.

Again, we have some choppy

and uneven areas in the pink part of the ears. There are also some

jumps within the same color which are totally unnecessary and

unavoidable and, once again, the solid eyes are broken up into chunks

rather than continuous, free-flowing solid shapes.

The black stripes and tail

are all satin stitch and some of them appear to be too wide to use a

satin fill. Some machines won't stitch wide satin stitches and

they can also snag easily. Those areas should be a split satin,

where the machine will make some extra stitches to keep the stitch

length shorter in the wider parts. The one time you DO NOT want to

see satin stitches split is on a satin applique border. That means

the satin outline is too wide.

Overall

results? Bad, but possibly usable with lots of cleaning up (in my

opinion).

On to the next...

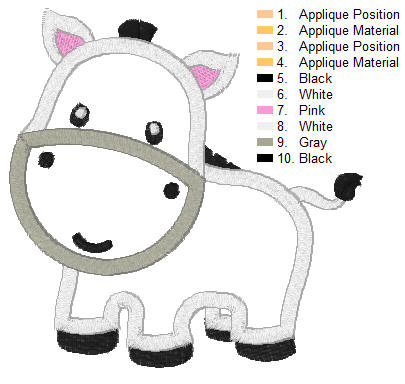

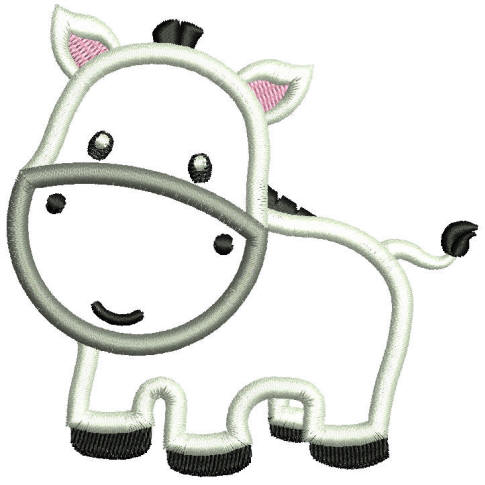

I used Brother's PE-Design

software to manually digitize the same zebra in applique form, and I did

the sloppiest job I possibly could! Just a little note...PE-Design

is a full digitizing program and it is actually the first program I

started with, but it is VERY limited in what you can do with a design.

I think it is great software for personal use but not professional use

(personal opinion). If you do decide to give it a try (it is very

simple and easy to learn as far as digitizing software goes) keep in

mind that its tie offs are poor and you will need to manually draw lock

stitches, it doesn't render curves or corners well but you can work

around that with the manual punch tool and extra nodes and I always

manually drew my underlay stitches as well. A good, very experienced

digitizer can work around software limitations. That being said, I

didn't take any of those extra steps in my example of poor digitizing.

(You can download this sloppy applique design

HERE)

Let's take a look at what

I threw together in about 30 minutes:

We'll look at it piece by

piece. First are the placement and tack down stitches. I

intentionally left these sloppy with overlapping pieces.

Overlapped fabrics can show through and cause thick, uneven areas for

the machine to stitch over. Most of the time these can be

eliminated.

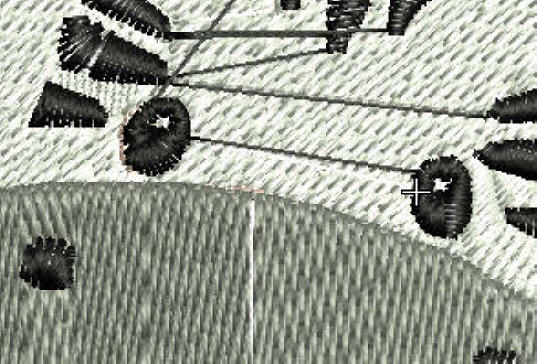

Next are the ear details.

This step has no underlay and an unnecessary jump that can

be eliminated. In applique designs you really shouldn't see any

jumps in the first few layers, especially in the satin outlines.

They can almost always be eliminated with some extra effort from the

digitizer. Jumps between eyes or within detail steps that stitch

last are normal and can't be avoided. Jumps early in a design,

especially within the satin steps, are telltale signs of a design that

was put together quickly (make more designs, sell more designs!) or

possibly the work of an inexperienced digitizer. Most of the time

they can be trimmed and you will never know they were there but why make

more work for the embroiderer and slow the machine down since it has to

stop and tie and trim and jump and then move on to the next part of the

design? I prefer to keep it flowing.

Next are the black

details. Again, no underlay, the satin applique outlines are too

thin and multiple unnecessary jumps which can almost completely be

eliminated. The mouth is sloppy with open, boxy ends. All of

the details are the same stitch direction and angle. The mane and

hooves are very tiny pieces of fabric that would work better in a filled

stitch and the way PE-Design rendered the corners is odd and not

visually appealing. Those

overlapped corners are unattractive and are hard on your machine, not to

mention bulky where the threads sit on top of each other.

Next is the white satin

outline. This is a total disaster!! ALL of these jumps can

be eliminated with the exception of the whites of the eyes. Again,

no underlay, satin is too thin. Filled areas are the same angle

and direction.

Last we have the snout.

Is that what it's called on a zebra?! Anyway, the satin is too

thin and there is no underlay. Also, see how it looks kind of

wobbly and wonky? That's how PE-Design renders curves and I didn't

bother to clean it up.

Let's take one last look

at this example of a BAD design.

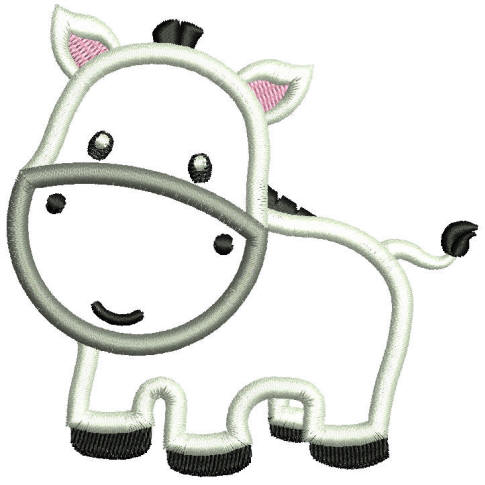

And here is the finished

design.

Surprising, isn't it!

You probably thought it would look much worse. This scares me because I might

purchase a design based on a photo like this if I didn't know better. This was a nightmare

to stitch. It jumped all over the place so my machine was stopping

a lot and I had some shifting since there was no underlay. Also,

the tie-offs are inadequate and I had a LOT of unraveling. My tack

down stitches unraveled so the fabric wasn't secured well and there were

loops at the beginning of all of the satins because the tie-in was just

not good, only two stitches! The lack of a good tie-in also caused

loops on the mouth. The hooves shifted a bit which left one edge

of the fabric completely exposed.

The fabric will probably pull out from under that thin satin (remember,

this design has NO underlay). This is a good example of how a

decent-looking

finished design has nothing to do with the quality of the design. A terrible design can actually look OK

when finished. It doesn't make it any less terrible, though!

This design was very unpleasant to stitch and will not hold up over

time. I doubt it would last through one wash on a T-shirt.

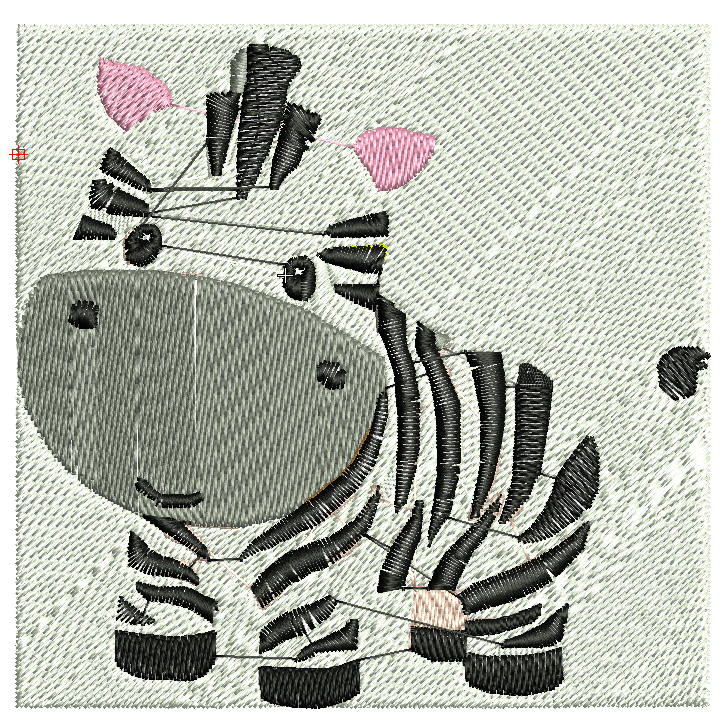

Last but not least, I

manually digitized the same zebra clipart in Wilcom Embroidery Studio 2

and I took all of the extra steps to make this design stitch out great.

Not only is the finished product going to look awesome, this design is

going to be easy and stress-free to stitch!

Let's look at some of the

features that make this design a good one.

No overlapping fabric pieces.

No unnecessary jump stitches.

The ONLY jumps in this design are between the facial features. And

folks, WE HAVE UNDERLAY! A good design rests on a good foundation.

The satin stitches are wide

and the design is smooth, not wobbly and wonky looking. The teeny

tiny applique pieces have been changed to fill stitches. The fill

stitch areas have appropriate stitch angles and push and pull

compensation applied. No shifting, no gapping, no bunching.

The mouth is rounded out and smooth. No more chop-block ends.

The mane and tail have cute details enhanced.

In a nutshell, this design

has been properly sequenced to minimize color changes, jump stitches and

overlaps, a variety of stitch types and angles are used to balance out

the push, pull, and flow of the design, underlay is a strong foundation,

wide satin stitches secure your fabric and it's CUTE! (You can

download this adorable and easy-to-stitch applique design

HERE)

I hope this helps to

explain what to look for and what to avoid when looking for quality

applique and embroidery designs. There is so much more information

that I don't have room or time to type out! Here are some

side-by-sides to help you compare: